ARISE Experiments

VITAWELD

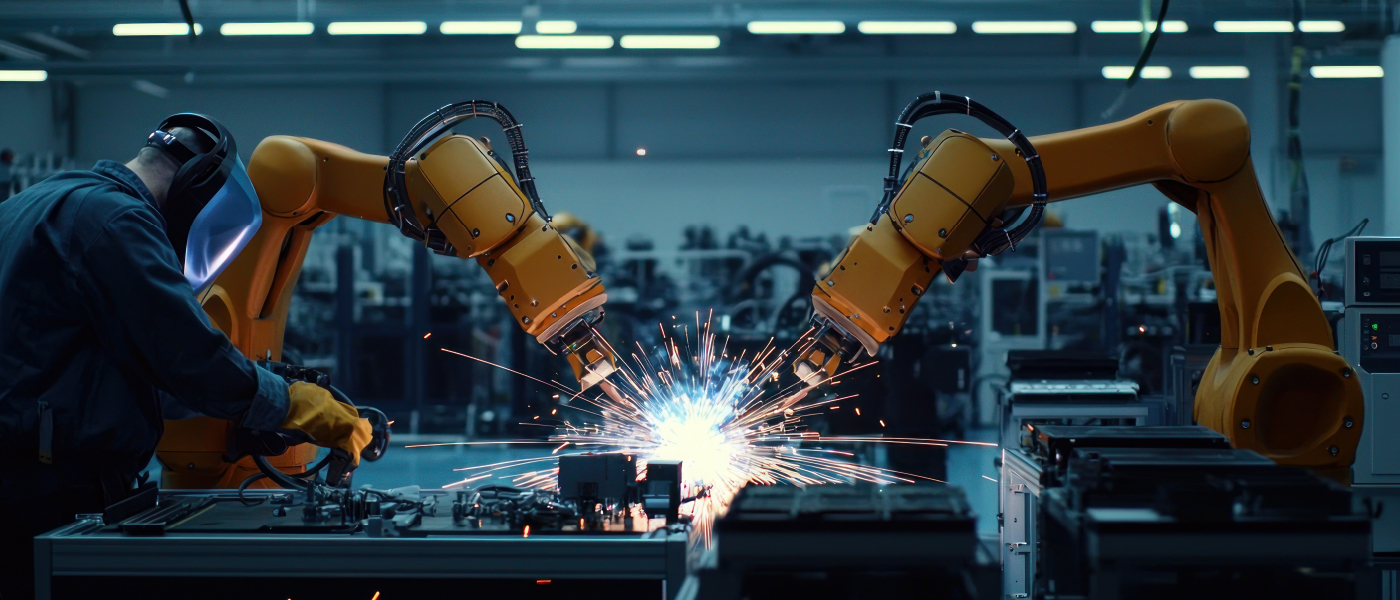

Vision & Human-Robot Teaming for Enhanced Welding

VITAWELD seeks the development of an intuitive vision-based system for human-robot collaboration in industrial welding, combining AI and natural interfaces to enhance operator capabilities while ensuring quality control.

The Challenge: Tackling Challenges in Industrial Welding

Industrial welding of large metallic components faces heat-induced distortions, complex robot programming requiring specialized expertise, defects like cracks or porosities, and inefficient manual parameter adjustments. These issues lead to costly rework, material waste, and safety risks. VITAWELD addresses them by enabling intuitive human-robot interaction, real-time monitoring, and AI optimization, making welding more efficient and accessible.

Our Solution: AI-Powered Collaboration for Precision Welding

VITAWELD combines Rovimatica’s computer vision with IDONIAL’s manufacturing expertise, using ROS 2 and FIWARE for modular automation. Natural language processing allows voice-based programming, while AR visualizes paths and parameters. AI detects defects in real-time and optimizes processes.

Key features include:

- Intuitive Programming: Use natural language and augmented reality to define and modify robot tasks in real-time.

- AI-Powered Quality Control: Real-time computer vision monitors weld quality and detects defects, giving operators immediate feedback.

- Modular Architecture: Built on ROS 2 and FIWARE for seamless integration and scalability across different industrial contexts.

- Operator-in-the-Loop: AI and automation act as a support system, empowering the human operator as the central decision-maker

Human Centricity: Empowering Welders for Safer, Smarter Work

VITAWELD challenges the traditional view of automation by prioritizing the operator. The system reduces physical strain and exposure to hazardous conditions, while enhancing worker capabilities through real-time insights and intuitive interfaces. With multi-language support, ergonomic designs, and configurable layouts, we ensure a more inclusive and accessible workplace for all.

The ARISE Contribution: Advancing Industrial Automation with ARISE

VITAWELD leverages ARISE middleware (ROS 2 and FIWARE) to deliver a modular, scalable framework for welding automation. Its interoperable components — HRI programming, vision monitoring, and process optimization — support seamless integration and adaptability. By advancing standardized solutions, VITAWELD contributes to ARISE’s mission of promoting flexible, human-centric automation for welding and related manufacturing sectors.

Impact & Scalability: A Future of Smarter, More Sustainable Manufacturing

VITAWELD targets the $8.6 billion industrial HRI market (22.8% CAGR as of 2025), with a $1.2 billion segment for large-component welding. It offers 30% improvement in quality rates, 40% reduction in adjustment time, and 25% less training, benefiting sectors like aeronautics and automotive. By cutting waste and energy use (up to 15%), it aligns with EU Green Deal goals, driving sustainable, cost-effective manufacturing innovation.

Partners

Discover more about ARISE experiments and how we’re

building the future of robotics for a better society!